-

Our company attaches great importance to the quality of our products. Whether it is the choice of treadmill body material, the fine debugging of assembly space, or the stringent requirements between the parts, every process will reflect the mission of our company. Our huge investment in the production process is to present consumers with humanized details of design and an optimal experience through qualified treadmills.

The mold cost of a single product is more than 3 million yuan, which is 5-10 times of the traditional mold cost. Besides, many parts are even custom-made. In the production and manufacturing, we have an outstanding quality control department with inspection groups to carry out effective quality control of production processes from raw materials into the factory to the finished product. Our testing room carries out a comprehensive test and service life test of each batch of products, which guarantees the products meet quality standards. At the same time, our exported products are certified by CE, FCC, UL and other international product certification systems.

Under the treadmill test stand, we test the durability, wear resistance and structural stability of each component of the treadmill after being subjected to gravity impact by using 75KG tires to impact the treadmill running deck at a frequency of 30 times per minute at a height of 10mm from the running belt.

After 300 hours of testing, the running deck and the running belt are not broken, the motor shaft is not deformed, the motor works normally, the bearings in the front and the rear rollers are not scattered, and there is no obvious abnormal sound, so as to detect the service life of the treadmill and the wear and tear of the components in long-term use.

We use the blast drying oven to check the use of electronic parts in a high temperature environment and the state of other materials in high temperature environment.

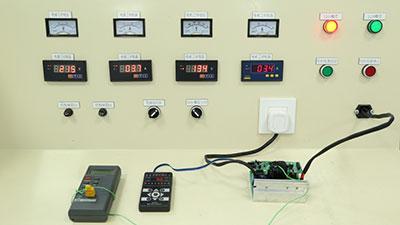

Test the load parameters of the controller, such as output / input voltage, output / input current, to ensure the service life of the electronic devices on the power supply board in high load condition for long-term operation.

Test the quality and service life of motor at the high-speed of 12KM/H, medium-speed of 9KM/H, low-speed of 4KM/H in high-load condition for long-term operation.

We carry out voltage withstand testing, insulation resistance testing, leakage current testing, and grounding protection testing for the treadmill power board in order to verify the quality of the electronic components of the power board, and ensure the quality of the products meet the standards.

In the case of no less than 100,000 times, ensure that all the treadmill buttons materials meet the design requirements, production assembly requirements and consumers’ requirements.

Ensure the hardness of treadmill screw, aluminum and metal parts meet production requirements, so as to ensure product quality.

In order to improve product reliability, we will simulate the impact of transportation environment on the product to identify and eliminate the early failure caused by unreasonable product structure, process and installation of components to ensure the overall quality and expected life.

Press the carton edge until the carton is crushed. We test the maximum endurance of each sample to ensure that the material of the treadmill carton can meet the requirements of R&D design, packaging and product transporting requirements.